About Us

Leadership

Mark Shickel

President

Vision

To be the most trusted name in the design, fabrication, and installation of custom metal products.

Mission

Shickel Corporation is a company of people with the experience and craftsmanship required to meet the challenges of our discerning customers. Our team designs, fabricates, and installs exceptional custom metal products. In all things we endeavor to honor our Lord, pursue excellence with integrity, and create value for our customers, co-workers, stakeholders, and community.

Safety

Shickel Corporation is committed to safety in the workplace, both yours and ours. Whether we are working on-site in your “confined space” or at our facility spray painting your products, we work hard to prevent all possible hazards to people and property. Each department has a monthly safety meeting for training in best practices, brainstorming better ways to work safely, and providing feedback to management. In addition, we have a monthly all-employee safety meeting for everyone to be trained in the best practices. To have a safe, healthy work environment for our workers, we participate in OSHA’s voluntary compliance inspection program.

The formal safety program at Shickel Corporation consists of several parts. It is designed around the following beliefs:

1. If a job or task cannot be done safely, it should not be done.

2. Job procedures and safety procedures cannot be separated. Every job will be done with safety measures included in every phase from quoting to delivery and installation.

3. All necessary steps will be taken to prevent accidents from happening.

4. Our employees will work as a team and be safe as a team.

Safe work behaviors will be demonstrated by assessing hazards, planning all work, and engineering safe workplaces and practices.

History

1938

1940

1940s

1940s

1940s

1955

1956

1960s

Late 1970s

Early 1980s

1980s

1985

1989

1990

1994

1994

1996

Early 2000s

2003

2006

2007

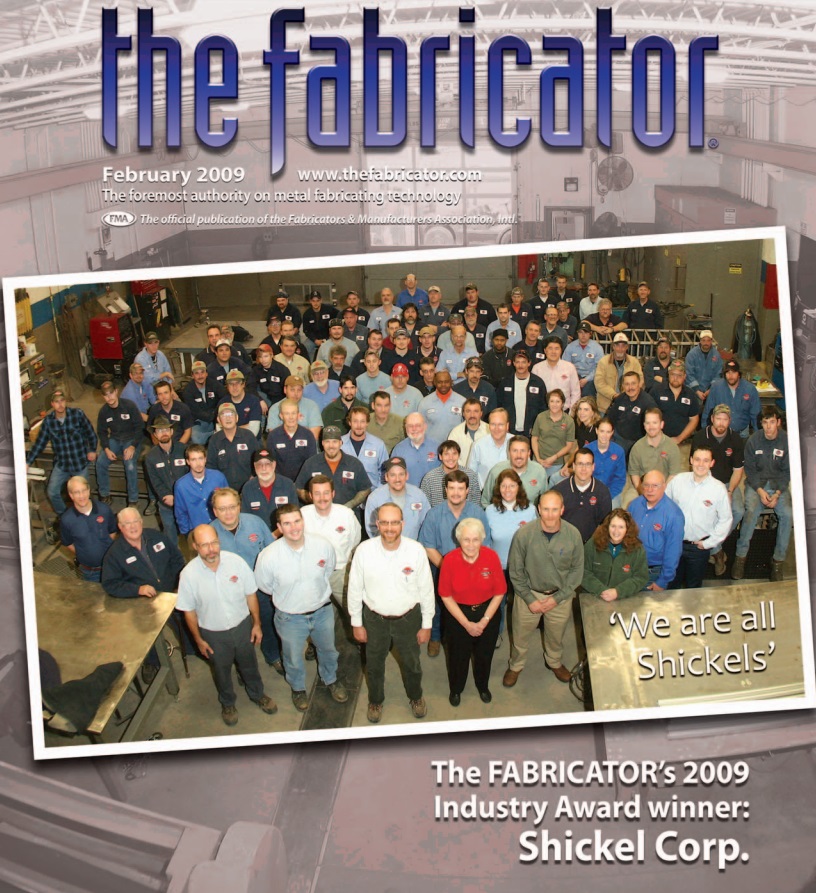

2009

2014

2015

2016

2018

2019

Shickel Present Day